January 2024, Rochester, New York (USA)

Gleason introduces the new online selector for its renowned LeCount® Expanding Mandrels. Customers can now select required mandrels from Gleason’s standard range or request special LeCount mandrels with just a few clicks, including simple re-orders and certification services for mandrels in use.

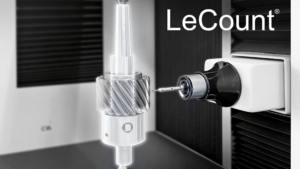

Gleason has launched a new online selector tool for its popular line of LeCount Expanding Mandrels that greatly reduces the time and effort needed to exactly match any standard or special LeCount Mandrel to the application. The LeCount Mandrel, patented by Charles W. LeCount in 1866 and continuously improved on over the last decade by Gleason, is considered the industry’s leading expanding mandrel solution for inspection applications, as well as for prototyping tasks and small lot manufacture.

Just one expanding mandrel can cover a large number of applications. This cost-effective and high-precision solution makes LeCount Expanding Mandrels the first choice when it comes to clamping bore-type parts on metrology systems and prototyping work. The patented, tool-less design of the LeCount mandrel is based on the principle of parallel expanding jaws that slide smoothly to grip the inside diameter of the part. The expanding mandrel itself is then placed between centers of the metrology system or manufacturing machine. Simple handling combined with high precision clamping provides for excellent concentricity with errors of less than 2.5 µm over the entire clamping length. It is the perfect clamping system for all bore-held workpieces, whether gears, turned parts or similar components.

LeCount Expanding Mandrels feature bore clamping diameters from 6.5 to 177 mm and are available in different versions: with two clamping sections to cover particularly wide ranges, with only one clamping section for long parts, as compact version if distance between centers or weight is an issue, for very small diameters, or for hob inspection. In addition, G Type Production Mandrels feature a stronger clamping force and are protected against contamination, particularly well-suited for prototyping and small lot manufacture on lathes, turning of parts with smooth bores, hard turning, or OD and face grinding. Optionally, all mandrels can be equipped with part locators for horizontal positioning, or designed as Spline Mandrels for parts with splined bores.

Visit www.gleason.com/lecount-selector to experience the new LeCount Mandrel Selector.

Gleason is a global leader in gear technology. Gleason’s “Total Gear Solutions” range from gear and transmission design software to the development and production of gear manufacturing machines and related accessories, gear metrology equipment and automation systems. Gleason products are used by customers in the automotive, commercial vehicle, aerospace, agricultural, mining, energy, construction, power tool, marine and many other industrial equipment markets. Gleason has manufacturing facilities in the U.S., Brazil, Germany, Switzerland, India, China and Japan, and operates sales and service offices in North and South America, Europe and Asia Pacific. For more information about Gleason Corporation, please visit www.gleason.com

Gleason and LeCount are registered trademarks of The Gleason Works, Rochester, NY (USA). All rights reserved.

For further information please contact:

Christian Albrecht, Chief Marketing Officer

Gleason Corporation, 1000 University Ave, Rochester, NY 14607, USA

calbrecht@gleason.com